In this guide, we are going to consider how to start a car with a bad crankshaft sensor. A functioning crankshaft sensor is crucial to the function of your vehicle. If it malfunctions, your vehicle will be unable to start and/or operate. Fortunately, you can test the crankshaft sensor using a basic multimeter as long as you have a general idea of how a car works.

Step 1: Check the crankshaft sensor

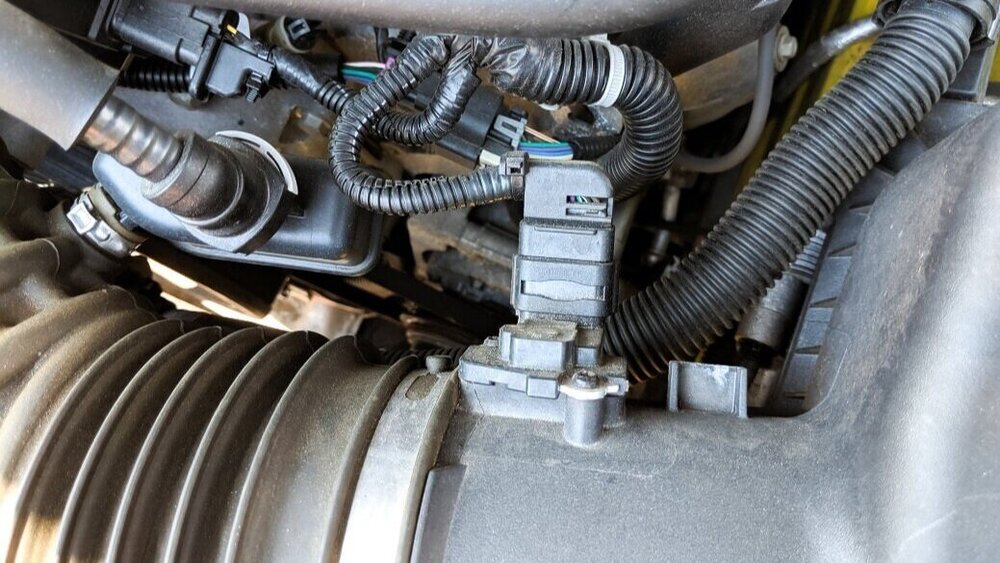

You can determine if the crankshaft sensor is working correctly by checking for a broken wire or loose connection, a bad ground, and a bad power wire. If any of these conditions are present, then it’s likely that the crankshaft sensor will need to be replaced.

Step 2: Find the ground wire and the power wire

Before you start connecting wires to the sensor, you should find out where the power and ground wires will be coming from. To do this, look at your car’s owner’s manual. The wire colors are often listed in there, or they may even be labeled on the engine itself! If neither of those options work for you, then go ahead and check out a wiring diagram online—you want to make sure that you’re connecting the right wires before attaching them to anything else.

Step 3: Disconnect the crankshaft sensor wires

- Disconnect the crankshaft sensor wires. You will need to detach the black and red wires from the crankshaft sensor.

- Don’t disconnect or touch any of these wires with your hands or a metal tool (like a screwdriver). This can cause arcing, which could damage them and make it impossible for you to start your car again.

- If you’re using a jumper wire, don’t let it come in contact with any metal surface—including your hands—while you’re working on this project; doing so could ground out one side of the battery pack if there’s not enough space between surfaces for an electrical current to pass through freely.

Step 4: Connect a jumper wire to the positive terminal of your car battery

Now, connect a jumper wire to the positive terminal of your car battery.

If you don’t have a friend or family member nearby who can lend you their jumper cables, you may be able to find one somewhere else: try a battery charger (like this one) or even just another working car with someone inside it. If none of these options are available, see if there is someone nearby who can help jump-start your car with theirs—but only do this if absolutely necessary!

Step 5: Connect the other end of the jumper wire to the power terminal on the crankshaft sensor

The remaining end of your jumper wire should be connected to the positive terminal of your car’s battery. This is a simple task that can be completed by simply removing a few screws and connectors.

Step 6: Find a ground wire (preferably one that is clean) and connect it to the ground terminal on the crankshaft sensor

Step 6: Find a ground wire (preferably one that is clean) and connect it to the ground terminal on the crankshaft sensor.

The ground wire should be free of rust, and able to handle at least 10 amps in order to start your car. It should also be able to handle the current needed to keep your car running while you drive.

Step 7: Turn on your ignition and start your car!

- Turn on your ignition.

- Start your car!

- Drive safely.

You can start your car if you know how to diagnose and problem solve with a bad crankshaft sensor

You can start your car if you know how to diagnose and problem solve with a bad crankshaft sensor.

What is a crankshaft sensor?

The crankshaft position (CKP) sensor tells the computer where the engine is at in its rotation. It’s part of the ignition system, which helps control when fuel gets injected into the cylinders, what spark plug fires first and how much fuel is put into each cylinder during combustion. If there are any problems with any of these systems, it can cause rough idle or stalling at idle speed.

How does it work?

A CKP sensor has two parts: A magnetic pickup that detects pulses from each tooth on the flywheel/flexplate (which spins with one end attached to your engine block) and an electrical connection that sends those signals through wiring to various computers within your vehicle’s computer system (ECM).

This allows for more accurate control when firing multiple cylinders during combustion by making sure that all cylinders fire at exactly the same time—preventing misfires caused by variations between cylinder firings or incorrect spark timing due to out-of-sync firing patterns among other things like worn piston rings which would cause pistons inside engines running dirty oil may not be able to compress enough air within their cylinders causing them not be able to ignite properly resulting in misfires because they aren’t getting enough oxygen from air being introduced into their combustion chambers due missing compression stroke–

Conclusion

Hopefully, we’ve gotten you more excited (and maybe a little less nervous) about embarking on a plant-based lifestyle. We know the struggle, and we came to these tips—even the one about watching badminton!—through our own trial and error. Remember that the important thing is to keep on trying. As we covered earlier, you don’t have to go super hard on yourself for slip-ups, because this journey can take time and looks different for everyone.

Plus, don’t forget that the best way to keep yourself on track is to keep it fun, keep it positive, and keep yourself engaged with the people and the world around you. After all, caring about others is a great reason to switch to this lifestyle in the first place!